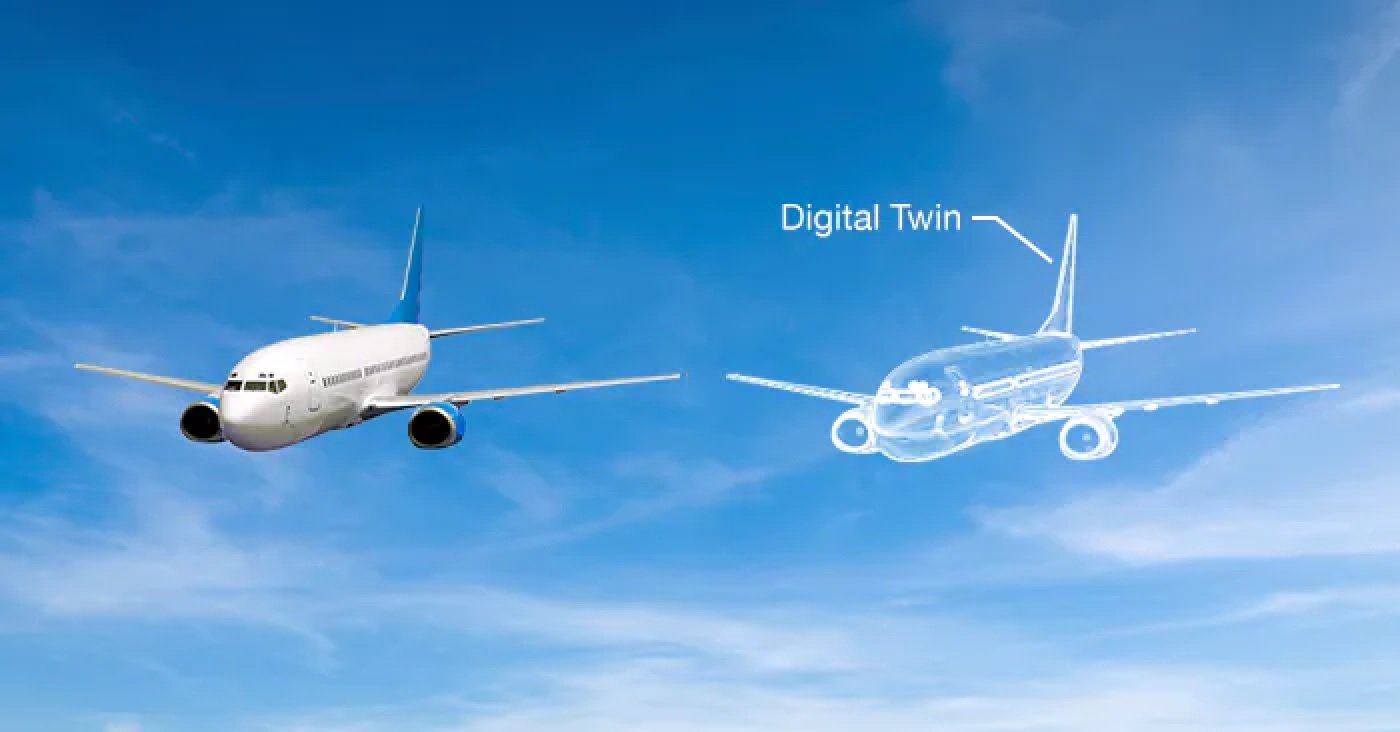

Digital twins—digital representations of real-world entities such as sensors, devices, machines, systems, and even people—have evolved from a niche concept to an integral part of the industrial landscape.

It is a fast-growing tech market as well: ABI Research forecasts that the industrial digital twin market will grow from $3.5 billion in 2021 to $33.9 billion in 2030, at a 29 per cent Compound Annual Growth Rate (CAGR), according to a report by ABI released on Thursday.

Clearly there is a need for digital twins, and the demand is driven by their performance.

A physical sensor stores data, and a person has to come and extract that data to use it. But the digital twin of that sensor stores the data in a way that permits real-time access. This means that it can be coupled directly to other computers and devices to generate actions or to deliver solutions much faster, according to the report.

A digital twin could, for example, collect data and then run a simulation using it that could be immediately applied to a real-life context.

Retailing provides a good example, according to researcher Softeq. In the retail industry, digital twins may come in handy both in the supply chain and in store. To create supply chain simulations, retailers use real-time sensor and equipment data, as well as ERP and other business system data. The models give an overview of supply chain’s performance including assets, warehouses, material flows, inventory positions, and people.

To create in-store digital replicas, retailers use data captured by RFID readers, motion sensors, and smart shelves. These models allow them to analyse customer movement and purchase behaviour, as well as test the optimal placement of products.

French supermarket chain Intermarché created a digital twin of a brick-and-mortar store based on data from Internet-of-Things-enabled shelves and sales systems. Now store managers can easily manage inventory and test the effectiveness of different store layouts.

Water utilities provide another example. Aguas do Porto (AdP), a Portuguese utility organisation, is responsible for the water supply in the city of Porto. AdP uses digital twins to forecast flooding and water quality issues, improve city services and responsiveness, and ensure resilience of water infrastructure.

The solution creates virtual models based on sensor and telemetry data together with the information across 20 other sources: customer service management, billing, maintenance, asset accounting, etc. Digital twins enable AdP to monitor the water supply systems in real time. They also are used to create forecasts on water consumption and simulate scenarios of pipe bursts along with valve and pump shutdowns.

Here are some other tasks that digital twins can perform in real life:

- “Brands and OEMs: Digital twins enable improved customer service, new revenue streams, and entirely new business models (e.g., Outcome-as-a-Service). This involves integrating digital twins of products with data sources including frontline workers, video/machine vision, and environmental sensor data

- Plant Managers: Digital twins drive better business process visibility across the facility and between systems by uniting critical data feeds, from design through manufacturing.

- Frontline Workers: Digital twins provide and catalogue real-time information for more efficient operations and better demand response.

- Operational Executives, such as Lean Leaders: Digital twins allow rapid, data-driven insights for the health and performance of assets and processes, with continuously updated sensor values and states.

- Engineers: Digital twins allow more rapid deployment of new applications in addition to simulations and scenario planning for business process optimisation.

The use of digital twins is leading to new business models: Greater control of assets and their data allows new business paradigms, like power-by-the-hour in the transportation industry or Data-as-a-Service for reporting on the performance of equipment on behalf of clients.

The vast usefulness of digital twins is the result of the convergence of innovations: Cloud-based data capture, data processing, data analytics, simulation and artificial intelligence (AI)-based decision-making.

“The sheer power of the cloud and analytics means that we can consider simulating things we could not possibly have simulated in the past,” says Appledore Research Group Principal Analyst Francis Haysom.

Click here to change your cookie preferences