Collaborative robots are the new hotness in industrial automation. Manufacturers in virtually every industry are eager to try them out on the plant floor, but there are a few things they should know before they do.

Collaborative robots will change your manufacturing business, especially if you’re working with limited floor space, small batch sizes, and frequent changeovers. The following are some of the things you need to know about cobots.

1 Cobots have been around for a while

Cobots have been around for a while, but the early models were expensive and limited to specific tasks.

The first collaborative robot was developed in the 1990s by the German company Unimate, eventually acquired by Universal Robots.

It was when manufacturing companies were outsourcing labor to developing countries with lower wages. Universal’s goal was to create robots that could work alongside humans and help keep production costs down.

Fast forward to today, and the cobot market is booming.

2 Cobots can work in a variety of industries

Collaborative robots (cobots) can work in various industries, performing tasks that previously may have been done by humans or not at all.

While industrial robots can automate manufacturing functions, cobots can be deployed for small-scale tasks to help humans be more efficient.

With cobots, safety is a top priority. Cobots have sensors that will immediately stop the robot if it gets too close to a human.

These robots also have software and hardware that guides their movements, moving more slowly than typical industrial robots.

Cobots are priced lower than traditional industrial robots as well. Manufacturers say cobots can also help with worker shortages by allowing older workers to perform tasks without heavy lifting or increased exposure to health risks.

3 They’re easy to use and program

Forget what you’ve heard about robots: Collaborative robots are easy to use. They don’t require years of training or programming experience.

You can teach a cobot the simplest of tasks with a wireless teach pendant, in which you physically guide the robot’s arm through the program’s motions step-by-step.

Some cobots are even easier to program, allowing users to grab the robot arm and move it into position simply. The cobot will remember the movements and repeat them when programmed to do so.

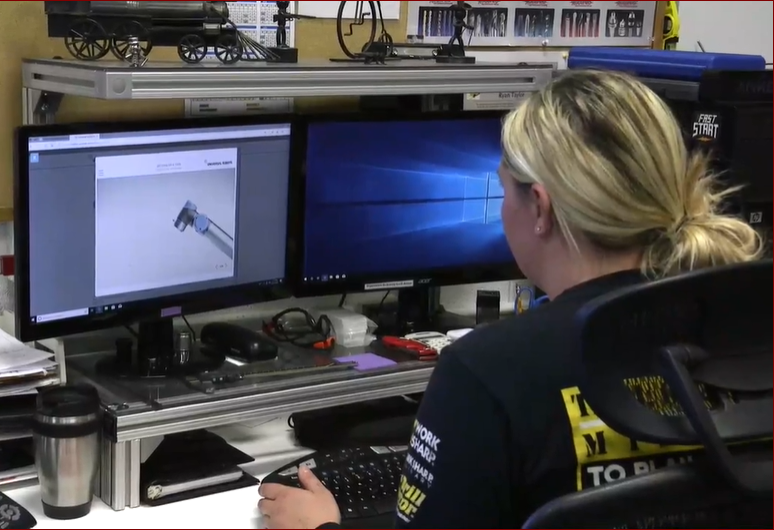

Modern cobots come with state-of-the-art software that allows for 3D visualization and offline programming for more complex tasks and high-precision applications. Users can safely program the robotic arm without risking collisions with other machinery or employees in the work cell.

4 They’re cheap

When you think of robots in manufacturing, you probably think of a massive, automated machine with a six-figure price tag.

That’s not the case with collaborative robots. The term “collaborative robot” is usually used interchangeably with “cobot,” which is short for “cooperative robot.”

A cobot is an affordable, small-scale robot that can work safely alongside humans. Cobots don’t have the raw strength of an industrial robot, but they are much more affordable than giant industrial robots.

They also don’t need to be isolated behind fences and cages because they are designed to work safely beside people without posing any physical harm.

5 There are lots of different Cobot types

There are many different types of cobots, and the more you know about them, the easier it will be to choose the right one for your application. Here’s a quick overview.

Articulated cobots: The arms on articulated collaborative robots can move in three or more directions (joints) to reach different work positions, just like a human arm. These robots are more versatile than other types but also more expensive.

SCARA robots: A SCARA (“Selective Compliance Assembly Robot Arm”) is an articulated robot with only two joints because its wrist does not move.

As a result, it’s cheaper than other articulated cobots and is often used in pick-and-place applications.

Delta robots: These robotic arms have three parallel joints that connect revolute pulleys and linkages to provide incredible speed and accuracy at a lower cost than other articulated designs. They can be designed to perform light assembly tasks or used as pickers in high-speed packaging applications.

Cartesian robots: Cartesian robots have three linear joints that coordinate motion along the X, Y, and Z-axis (i.e., up/down, left/right, and forward).

6 Cobots can be dangerous

Boom! That was an easy one. Well…no. The reality is collaborative robots aren’t inherently safe to work alongside people. They need to be designed and built to make them safe — and they also need to be used properly.

It’s like anything else: if you don’t take the proper precautions, things can go wrong. And when it comes to industrial robots and manufacturing automation technologies, things going wrong can be deadly.

7 Companies that make Cobots want to help you use them

Collaborative robots are excellent tools for manufacturers. They’re safe, flexible, and easy to program. They make automation accessible to companies of all sizes.

For some companies, cobots provide the first opportunity to automate tasks on the shop floor. With a wide range of applications at a low price point, these robots can be used in place of more expensive industrial robots.

As cobots become increasingly prevalent on the factory floor, they’re being used in novel ways never imagined before. Some customer applications are so exciting and innovative that they’ve caught the attention of cobot manufacturers.

These manufacturers know that it can be challenging to use cobots, and because of that, most of them will be willing to help users troubleshoot issues and operate these machines.

8 The Cobot market is growing fast

The International Federation of Robotics (IFR) forecasts that cobots will outsell traditional robots in the automotive industry by 2025.

Robotics and automation is a much-talked-about topic across all industries, particularly manufacturing.

The rise of collaborative robots, which can be deployed alongside workers without safety barriers, has opened up new possibilities for manufacturers and their employees.

Collaborative robots are set to open up new possibilities for manufacturers and their employees.

9 The U.S. trails Europe in adopting the technology

Collaborative robot sales have skyrocketed over the past five years. According to research firm ABI, these machines saw an annual growth rate of 60% between 2015 and 2017, and they’re expected to reach more than $5 billion in annual sales by 2025.

By then, so many companies will be using collaborative robots for accounting for about half of all industrial robot sales.

Despite this projected growth and their potential benefits-improved productivity, high return on investment, and greater flexibility — many U.S. manufacturers are still reluctant to use collaborative robots.

One possible reason for this reluctance is that American businesses may not fully understand how these robots work or what distinguishes them from industrial robots.

10 Cobots may be coming for your job

Automation is coming for your job, which is not necessarily bad. The automation of manual labor has been ongoing since the industrial revolution.

It has led to more leisure time and higher wages and greater productivity, and lower prices for consumers.

However, it has also contributed to the de-skilling of workers, who may find themselves unemployed in the medium term when their jobs are automated.

Final thoughts

Collaborative robots are here to stay and probably a lot closer to your factory floor than you think. They’re in the food industry, working alongside people to package meals.

They’re moving boxes in warehouses and stocking shelves in retail outlets. You’ll soon see them everywhere, from doctor’s offices to restaurants

Click here to change your cookie preferences