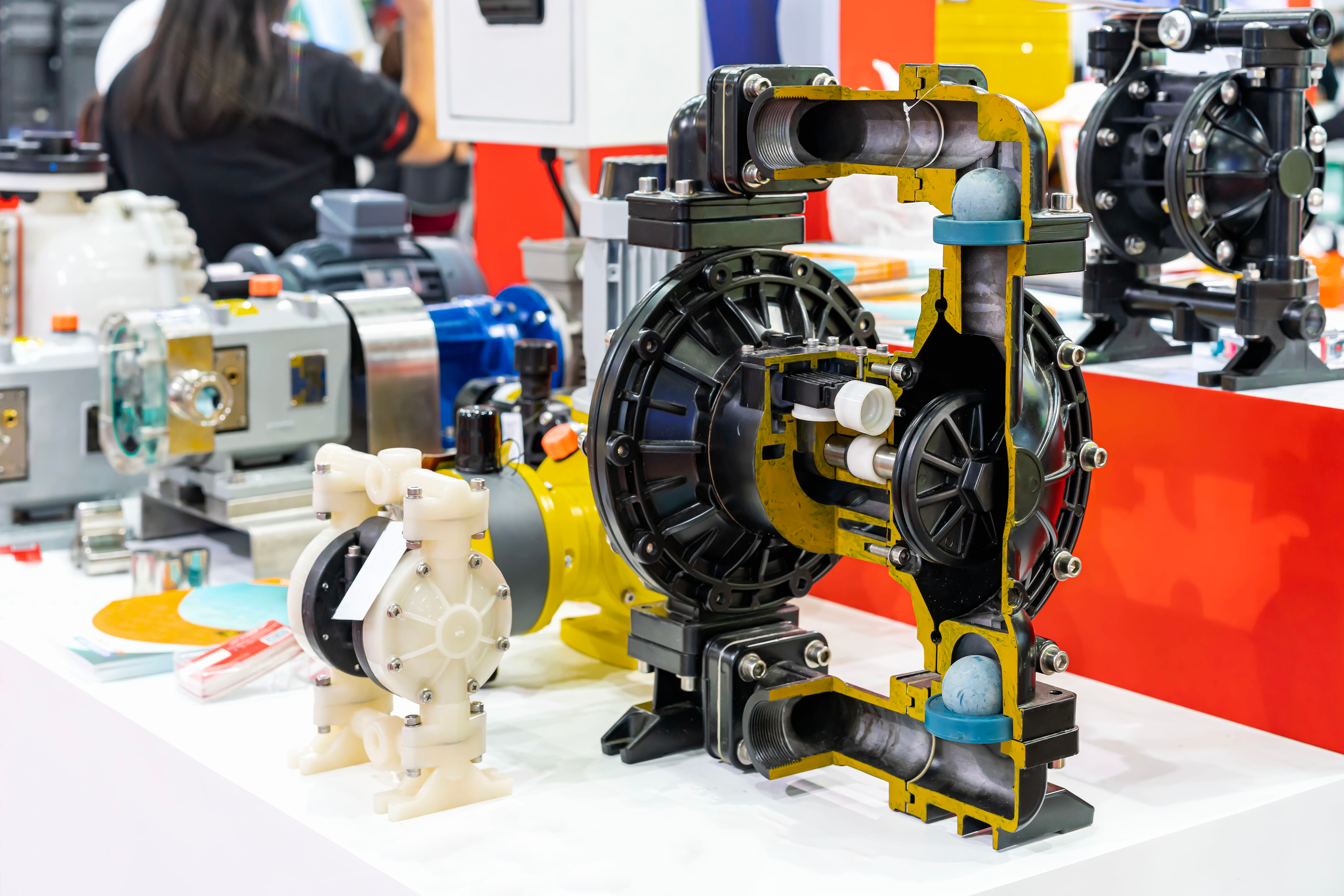

Within the industrial landscape, numerous operations rely on the controlled movement of liquids. A key player in this field is the diaphragm pump. This pump stands out from traditional options by employing a unique mechanism to effectively and reliably transfer fluids.

That said, this guide will explore the inner workings of the diaphragm pump, exploring its functionalities and the wide range of applications where it thrives.

What Is A Diaphragm Pump?

A diaphragm pump, also known as a membrane pump, is a type of positive displacement pump that uses a diaphragm to move fluid. It operates through the reciprocating action of a flexible diaphragm made of materials such as rubber, thermoplastic, or Teflon, combined with suitable check valves to pump a fluid. For more detailed information and technical specifications, you can visit online sites like knf.com/en/uk to learn more.

Functions of a Diaphragm Pump

Diaphragm pumps are widely used due to their unique design and operational characteristics. Here are the key functions of a diaphragm pump:

1. Positive Displacement

Diaphragm pumps are positive displacement pumps, meaning they move a fixed amount of fluid with each cycle. This makes them ideal for applications requiring precise dosing and metering of fluids.

2. Self-Priming

Diaphragm pumps can create a vacuum sufficient to draw fluid into the pump without needing to be filled with fluid beforehand. This self-priming capability allows them to start pumping immediately, even when dry.

3. Handling Various Fluids

These pumps can handle a wide range of fluids, including:

- Viscous Fluids: Thick, syrupy liquids.

- Abrasive Fluids: Fluids containing solid particles.

- Corrosive Fluids: Chemicals and acids.

- Slurries and Sludges: Mixtures of liquids and solids.

4. Leak-Free Operation

The diaphragm forms a barrier between the fluid and the moving parts of the pump, providing a sealed system that minimizes the risk of leaks and contamination.

5. Adjustable Flow Rates

The flow rate of diaphragm pumps can be easily adjusted by changing the speed or stroke length of the diaphragm. This flexibility allows for precise control over the amount of fluid being pumped.

6. Safe for Sensitive Fluids

The sealed design and gentle pumping action make diaphragm pumps suitable for handling sensitive or sterile fluids, such as pharmaceuticals and food products, degradation or contamination.

7. Dry Running Capability

Diaphragm pumps can run dry without damage, which is useful in situations where the fluid supply might be intermittent or where priming can be challenging.

8. High Suction Lift

They can achieve high suction lifts, allowing them to draw fluids from significant depths or distances, making them suitable for applications such as dewatering or sump pumping.

9. Resistance to Chemicals and Abrasion

Diaphragm pumps are often made from chemically resistant materials like Teflon, rubber, or thermoplastics, allowing them to handle aggressive chemicals and abrasive materials without damage.

10. Pulsation Dampening

While diaphragm pumps naturally produce pulsating flow due to their reciprocating action, many designs include features to dampen these pulsations, providing a steadier flow when needed.

These functions make diaphragm pumps versatile and reliable in handling a wide range of pumping needs across various industries.

Applications Of Diaphragm Pumps

Diaphragm pumps are versatile and used across many industries due to their ability to handle various types of fluids and their operational benefits. Here are some common applications of diaphragm pumps:

Chemical Processing

- Acid and Chemical Transfer: Handling corrosive chemicals, acids, and solvents.

- Dosing and Metering: Precise addition of chemicals in controlled amounts.

- Bulk Transfer: Moving large volumes of chemicals from one location to another.

Water and Wastewater Treatment

- Chemical Dosing: Adding chlorine, flocculants, and other treatment chemicals.

- Sludge Handling: Pumping thick, abrasive sludge materials.

- Filtration Systems: Moving wastewater through filtration systems.

Food and Beverage Industry

- Food Product Transfer: Pumping syrups, sauces, and juices.

- Filling and Packaging: Dosing precise amounts of product into containers.

- Sanitation: Handling cleaning and sanitizing solutions.

Pharmaceutical Industry

- Sterile Fluid Transfer: Moving sensitive fluids without contamination.

- Dosing and Metering: Precise addition of pharmaceutical ingredients.

- Bioprocessing: Handling fluids in bioreactors and other processing equipment.

Oil and Gas Industry

- Oil Transfer: Moving crude oil and refined products.

- Water and Glycol Transfer: Handling water, glycol, and other fluids used in extraction and processing.

- Chemical Injection: Dosing chemicals into pipelines and processing systems.

Automotive Industry

- Fuel Transfer: Pumping gasoline, diesel, and other fuels.

- Lubrication Systems: Distributing oils and lubricants to machinery.

- Cooling Systems: Moving coolant fluids in engines and HVAC systems.

Mining and Construction

- Dewatering: Removing water from construction sites, mines, and tunnels.

- Slurry Transfer: Handling mixtures of water and solids.

- Dust Suppression: Pumping water for dust control.

Paints and Coatings

- Transfer of Viscous Fluids: Moving paints, inks, and coatings.

- Spraying Systems: Pumping fluids into spraying equipment for application.

Agriculture

- Fertilizer and Pesticide Application: Dosing and spraying agricultural chemicals.

- Irrigation: Pumping water and nutrients for crop irrigation systems.

Marine Industry

- Bilge Pumping: Removing water from bilge compartments.

- Fuel Transfer: Pumping fuel to and from storage tanks.

- Wastewater Handling: Managing sewage and gray water systems.

HVAC and Refrigeration

- Coolant Circulation: Moving refrigerants in HVAC systems.

- Condensate Removal: Pumping away condensate in air conditioning systems.

Printing Industry

- Ink Transfer: Handling inks and other printing fluids.

- Solvent Handling: Moving solvents used in printing processes.

Laboratories and Research

- Fluid Sampling: Collecting samples of various fluids for analysis.

- Experimental Setups: Pumping fluids in experimental and pilot plant setups.

Diaphragm pumps are chosen for these applications due to their ability to handle a wide range of fluid viscosities, their self-priming capabilities, and their ability to operate safely in various environments.

Conclusion

With the secrets of the diaphragm pump unveiled, its potential becomes clear. This dependable workhorse isn’t just about brute force; it offers a unique blend of versatility and resilience. From handling delicate food products to conquering abrasive slurries, diaphragm pumps tackle fluid challenges with aplomb. As industries continue to push boundaries, the adaptability of the diaphragm pump ensures its place as a vital tool for the future.

Click here to change your cookie preferences