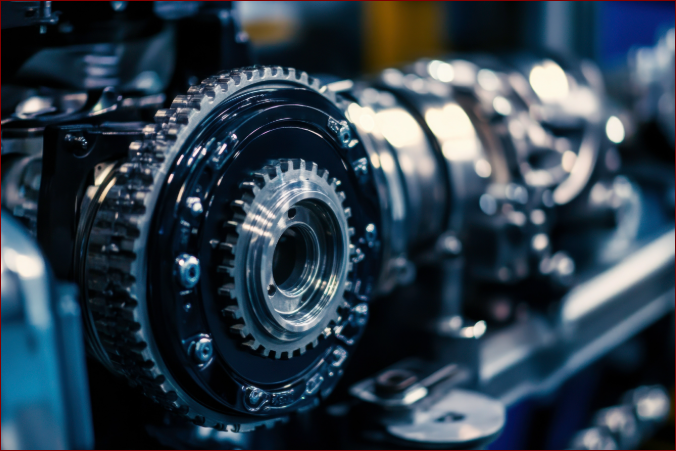

Precision ground gears are the quiet drivers of industrial progress, crafted with exceptional care to deliver flawless mechanical performance. Their finely machined surfaces and exacting tolerances allow complex systems to operate with minimal friction and maximum reliability. These gears make it possible to achieve smooth, efficient power transmission in even the most challenging conditions.

Beyond their technical perfection, they enable businesses to meet ambitious goals for productivity, quality, and innovation while reducing downtime and maintenance costs. As industries face rising demands for precision and efficiency, the role of these gears becomes even more critical, serving as essential components that keep modern operations moving seamlessly.

Read on to discover how precision ground gears truly power modern industries.

Enabling high-performance industrial machinery

Industrial systems rely on dependable components that deliver consistent results under tough conditions.

Below are ways precision ground gears support manufacturing industries:

- Consistent production quality: Precision ground gears maintain exact tooth surface profiles and tight backlash control spur gears tolerances, reducing variations in output and ensuring reliable performance even at high speeds. Careful heat treatment and finishing processes help these components endure demanding production cycles while delivering uniform results.

- Durability for heavy loads: Industrial operations often require robust solutions that can handle stress without premature wear. High-quality worm gears and bevel gears with optimized face width and pitch circle diameter specifications distribute forces evenly, extending service life and lowering maintenance costs. This allows production to continue with fewer interruptions and better cost control.

- Tailored designs for specific applications: From gear rack systems to custom spur gears, manufacturers can specify unique configurations and gear ratios that match their equipment needs precisely. It’s worth partnering with a specialist in high-quality bespoke precision gear manufacturing, such as ntgear.co.uk or another trusted supplier, to ensure every gear meets exact requirements. This investment supports reliable operation and smooth integration with existing systems.

Precision ground gears help industrial equipment achieve reliable, high-capacity performance while supporting cost-effective, uninterrupted production.

Unmatched accuracy and efficiency in motion control

Precision ground gears deliver the fine-tuned motion industries rely on to keep equipment reliable and productive.

Here are ways they deliver unmatched control and efficiency:

- Exceptional dimensional consistency: Careful use of gear grinding equipment ensures each gear tooth is finished to tight tolerances with optimal surface roughness. This consistency allows precise contact during rotation, minimizing vibration and noise while improving machine responsiveness.

- Engineered for exact fit: Accurate bore diameter and hub diameter measurements guarantee seamless integration with shafts and other precision machined components. This alignment supports stable motion control and reduces the risk of misalignment that can cause wear or failure over time.

- Optimized tooth geometry: Advanced design methods account for ideal pressure angle and custom profiles, enabling gears to deliver smooth load transfer under varying conditions. This level of refinement ensures dependable motion control across complex electromechanical assemblies where precision matters most.

These characteristics help industries achieve reliable, efficient movement in critical machinery while maintaining consistent production standards.

Driving innovation in aerospace and automotive engineering

Precision ground gears play a critical role in meeting strict performance requirements across the aerospace sector and automotive fields. These industries demand quiet, smooth operation to reduce noise and improve passenger comfort, relying on carefully engineered profiles that ensure seamless power transfer. Tight quality control during gear manufacturing delivers consistent results that support safety and reliability on the road and in the air.

Moreover, weight reduction is essential for improving fuel efficiency and overall performance in vehicles and aircraft. Manufacturers turn to advanced alloys and optimized gear cutting tools to achieve high strength-to-weight ratios, balancing durability with the need to minimize mass. This careful engineering allows designers to meet demanding specifications without compromising reliability or lifespan.

In addition, strict industry standards shape the production of these components to guarantee reliable operation under harsh conditions. Producers often certify their processes to ISO class 5 tolerances, ensuring every gear meets precise dimensional requirements. As a result, aerospace and automotive systems can depend on these gears for critical functions from differential end gears in drivetrains to complex assemblies in turbine systems.

Supporting renewable energy and emerging technologies

Precision ground gears play an essential role in advancing renewable energy systems. In wind turbines, they enable efficient power transmission even under fluctuating wind speeds and harsh environmental conditions. This level of reliability helps reduce unplanned maintenance and supports stable energy output.

Building on that, solar tracking systems also benefit from precision gear design. These systems depend on accurate, controlled motion to keep panels aligned with the sun’s position throughout the day. Over time, this precision improves energy collection and helps operators meet performance targets without constant recalibration.

Beyond renewable energy, these gears are increasingly vital to new technologies across various fields. From surgical instruments to automated production lines, applications require dependable motion and consistent quality. As these technologies continue to evolve, precision ground gears remain a key enabler of safe and efficient performance.

Final thoughts

Precision ground gears are more than mechanical components—they are the backbone of modern industry. Their exceptional accuracy, efficiency, and reliability drive progress across aerospace, automotive, manufacturing, and renewable energy sectors. As industries evolve and new technologies emerge, the demand for these expertly crafted gears will only grow, ensuring that precision engineering remains essential to powering the future.

DISCLAIMER – “Views Expressed Disclaimer: Views and opinions expressed are those of the authors and do not reflect the official position of any other author, agency, organization, employer or company, including NEO CYMED PUBLISHING LIMITED, which is the publishing company performing under the name Cyprus-Mail…more

Click here to change your cookie preferences